Drum Rim Remove Tool Drum De-Headers

+ Add to Quote RequestDrum lid removing tools are designed for serious operations that require a heavy-duty solution to remove lids from steel drums.

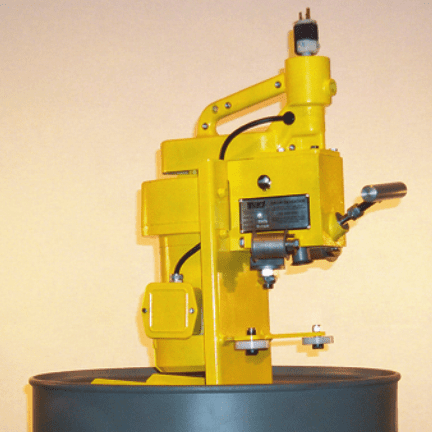

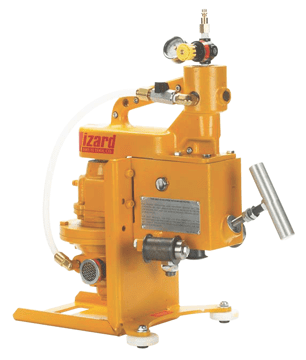

Three series of Wizard drum de-headers open steel drums easily and safely.

What version do you need? It depends on the application!

Additional Information

Electric models are chosen for quiet operation and when single-phase power is available.

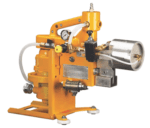

Air models are preferred in industrial settings where floors and work areas are wet.

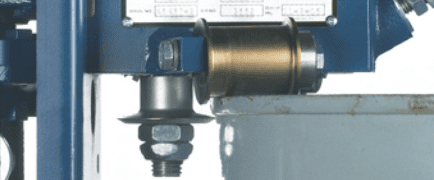

The automatic air model is effective when a large number of drums are being de-headed. This model automatically adjusts the gap between the cutter wheel and the drive roller. Manual adjustments have to be made on the electric and air models. Air and Automatic models are optionally available with non-ferrous cutter wheels.

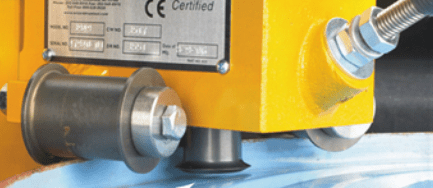

The G Series drum de-headers are the most versatile and popular models. They cut on the inside of the drum’s rolled edges, leaving a smooth, burr-free, “hand-safe” edge. The G series are ideal for de-heading a high to moderate volume of full and empty steel drums. The tool is capable of de-heading drums in less than one minute. Once de-headed, the drums are suitable for use as storage, shipping, or utility containers. The G series also easily removes the tops and bottoms of steel drums to facilitate their disposal. The G series self-propelled drum de-headers are available in air, automatic air and electric power. They can be easily converted to an outside cut if required.

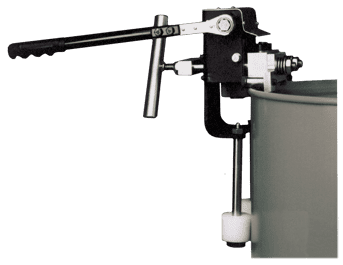

The J Series are specifically designed for scrapping drums. These de-headers cut on the outside of the drum shell so smooth, dent-free chimes are not required. They can remove the entire drum top and/or bottom for drum flattening in less than two minutes. Flattened drums take up less space and prevent potential liability from future drum use.

The F Series food quality models for use with food, pharmaceutical, or industrial drums where contamination risk must be minimised. They cut on the outside of the rolled edge, minimising the potential for contamination of the drum contents. The lid stays in place until lifted off. Fast – Portable – Easy

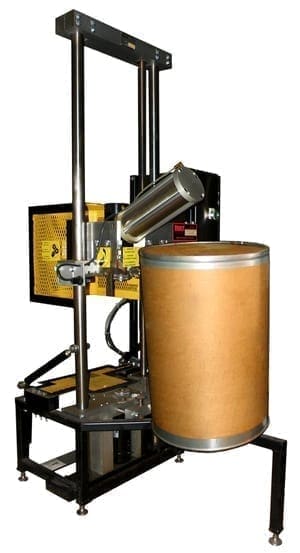

There is an optional Support Tower that keeps self-propelled drum de-headers at working height and minimises lifting. A complete de-heading station should include the tower as well as a de-header; chime de-kinker, universal wrench and spare de-heading tool. There is also an optional magnetic drum lid holder that can be used with the drum tower. It prevents the drum lid from falling into the drum after the lid has been cut.

View our Manual Drum De-Header our Drum De-Header Tools and our Manual WIZ-KID for more drum deheader products.