Drum Taps and Safety Valves

+ Add to Quote RequestThese faucets are all self-closing and incorporate an internal flame arrestor.

When selecting a safety faucet you should also decide on which safety drum vent you are going to use as both products should be installed at the same time to gain full protection from flashbacks during dispensing.

Drum Fill Gauges for use with vertically-stored drums during waste disposal operations. Avoid overfilling and dangerous overflow – our polyethylene pop-up gauges provide an economical way to prevent accidents.

Additional Information

Proper drum storage and dispensing protect personnel and property from fire hazards.

Two methods are acceptable for drawing off hazardous liquids from drums:

Two methods are acceptable for drawing off hazardous liquids from drums:

-

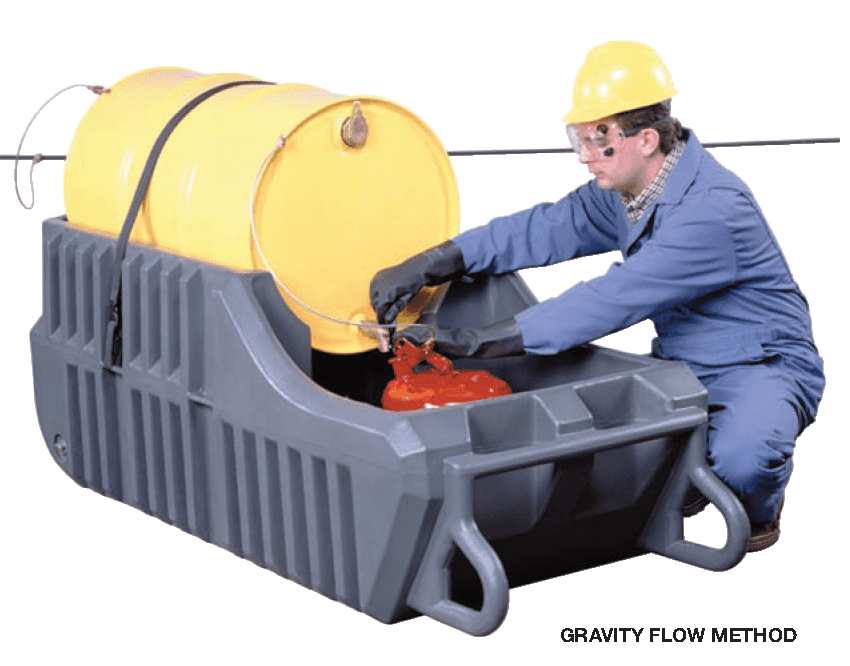

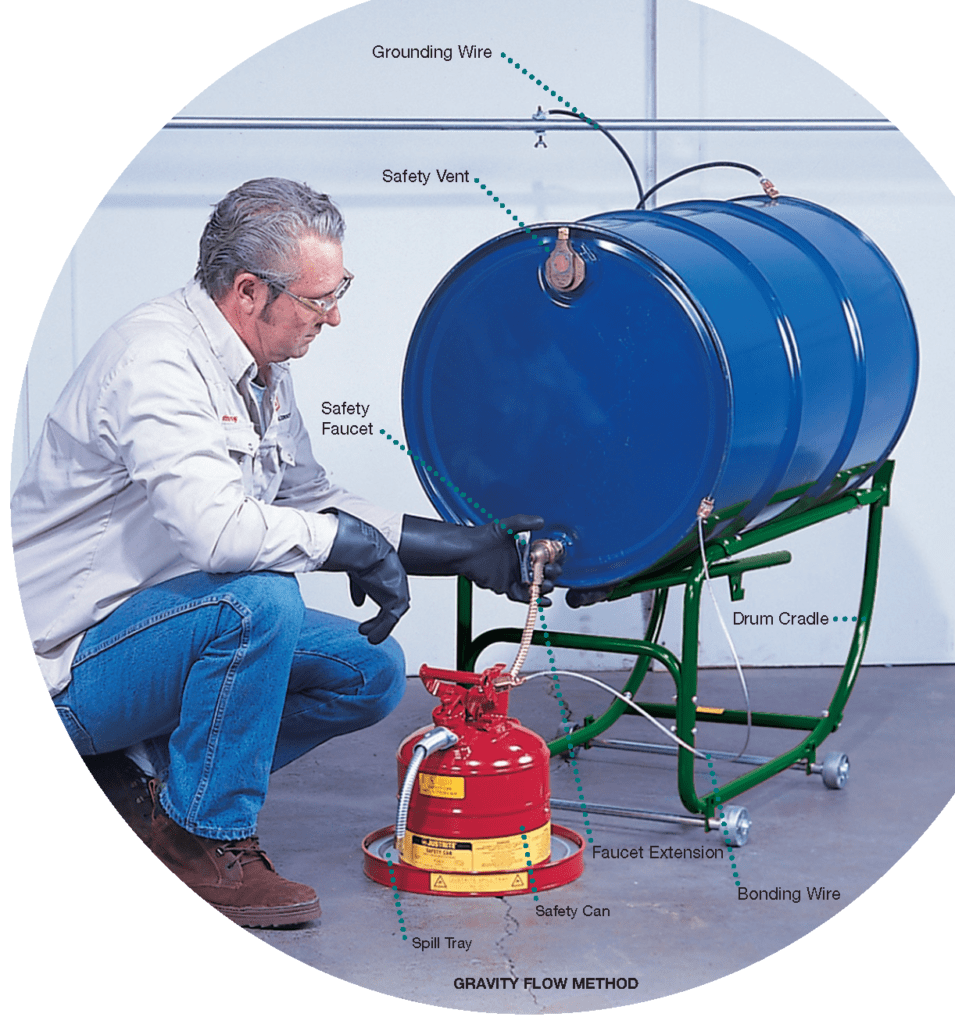

Gravity Flow Method

-

Pump Method

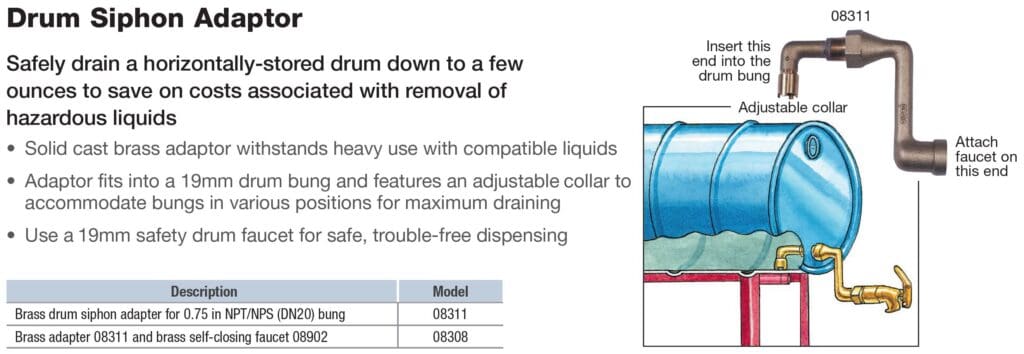

Gravity Flow Method utilizes a safety faucet that requires the drum to be in a horizontal position for dispensing. A device such as a drum cradle or drum caddy provides an easy way to move drums into position and support them for storage. Gravity flow method requires the use of a safety vent in the drum, spill tray or drip can under the faucet, bonding wire between the drum and the container being filled, and a grounding wire between the drum and an earth ground. In some jurisdictions, gravity flow dispensing is prohib-ited by code. Check regulations in your area. To withdraw liquid from vertically stored drums, there are a variety of pumps available on the market.

Proper grounding is required when dispensing flammables.

Draining or pouring flammable liquids can build up static electricity. This static electricity can easily cause a spark near the flammable liquid, which can ignite the vapors and cause an explosion and fire. To prevent static sparks when dispensing flammable liquids, OSHA requires that the nozzle and container be grounded. Specifically OSHA states:

“Class I liquids shall not be dispensed into containers unless the nozzle and container are electrically interconnected. Where the metallic floorplate on which the container stands while filling is electrically connected to the fill stem or where the fill stem is bonded to the container during filling operations by means of a bond wire, the provisions of the section shall be deemed to have been complied with” [Regulation 29 CFR 1910.106 (e)(6)(ii)].

Grounding and bonding wires help satisfy this requirement. Grounding wires connect the dispensing container to an electrical ground, such as a water pipe. Bonding wires connect the container to the safety can that receives the liquid.